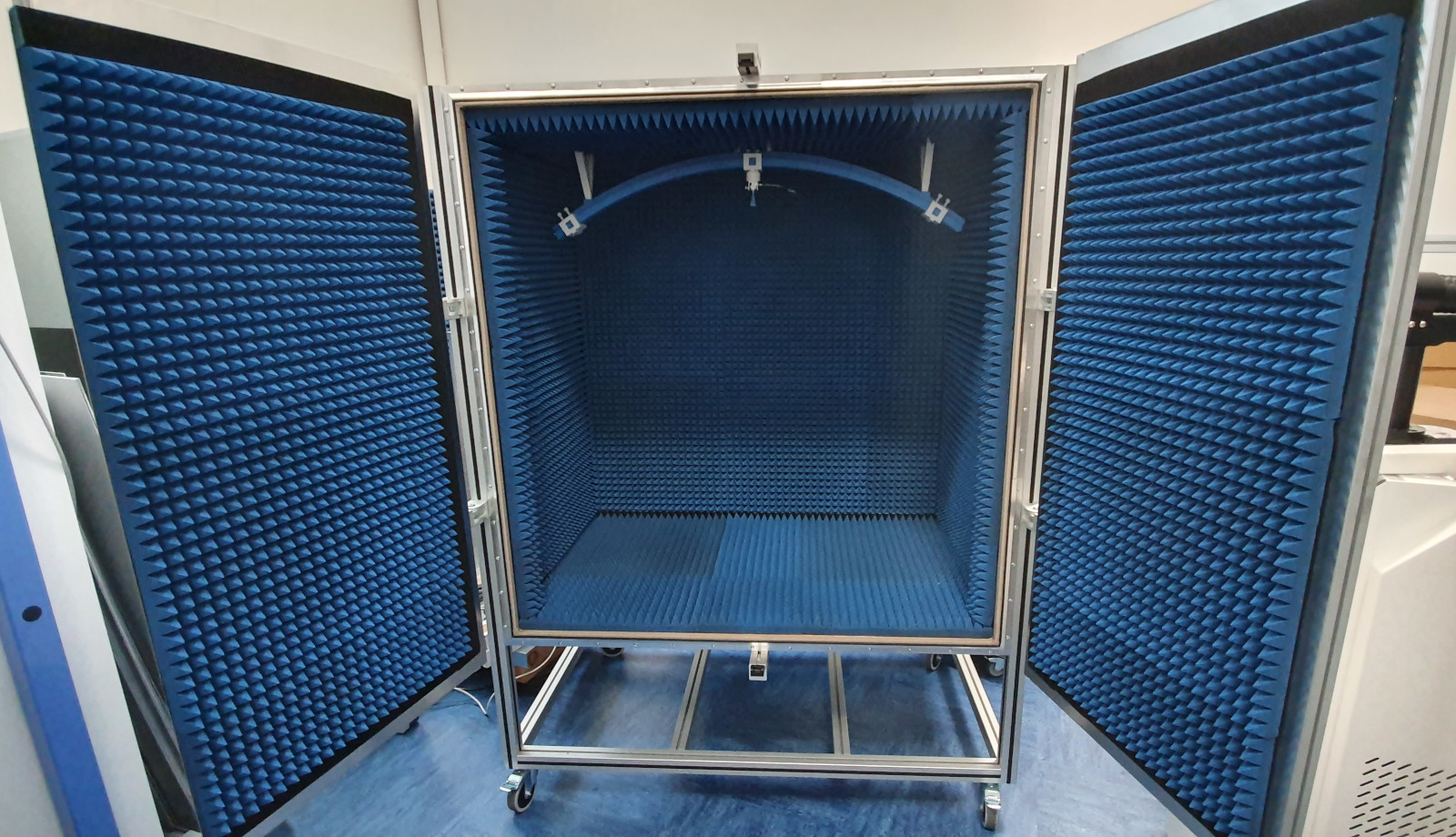

Mini chamber for RF (OTA) tests

Mini chamber made from a structure of aluminum profiles and aluminum plates. The interior is lined with RF-absorbing materials of the anechoic type.

RF sealing between the aluminum plates and around the doors is ensured by EMC gaskets.

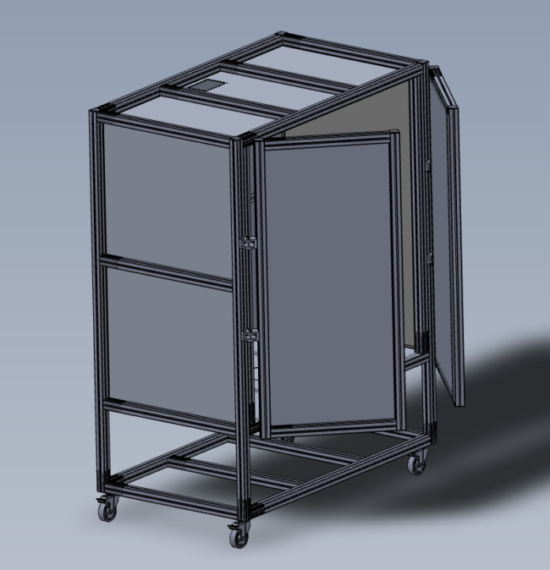

The design was created using SolidWorks, which allowed the entire chamber to be modeled and ensured that the dimensions were accurate.

You can view the 3D design of the structural part by clicking on the image.

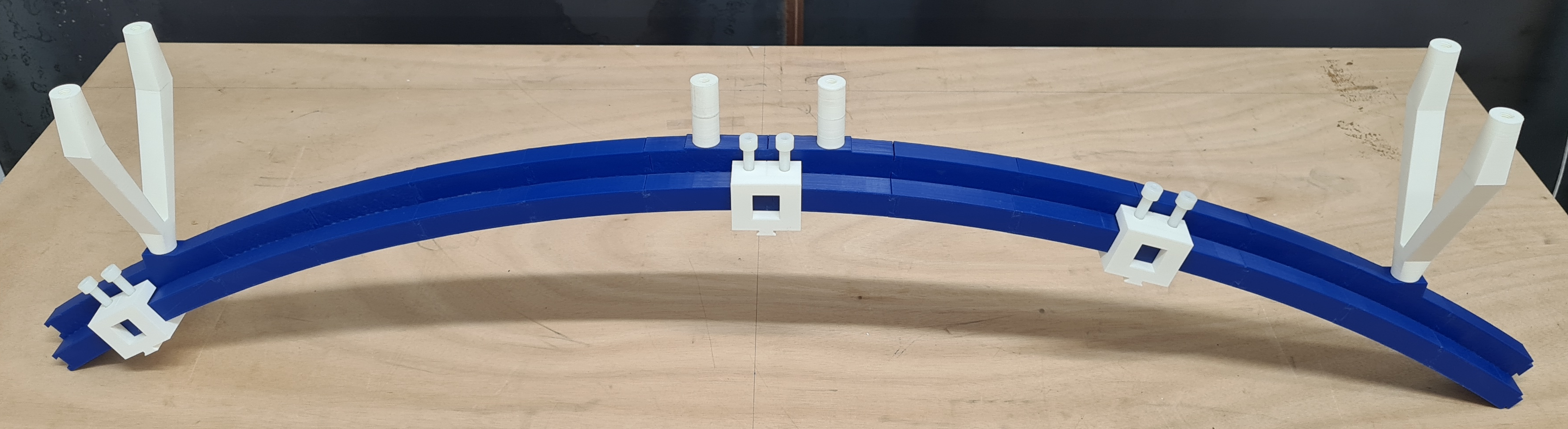

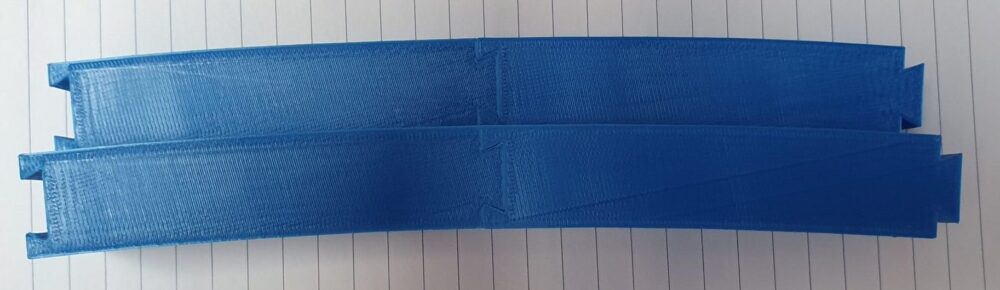

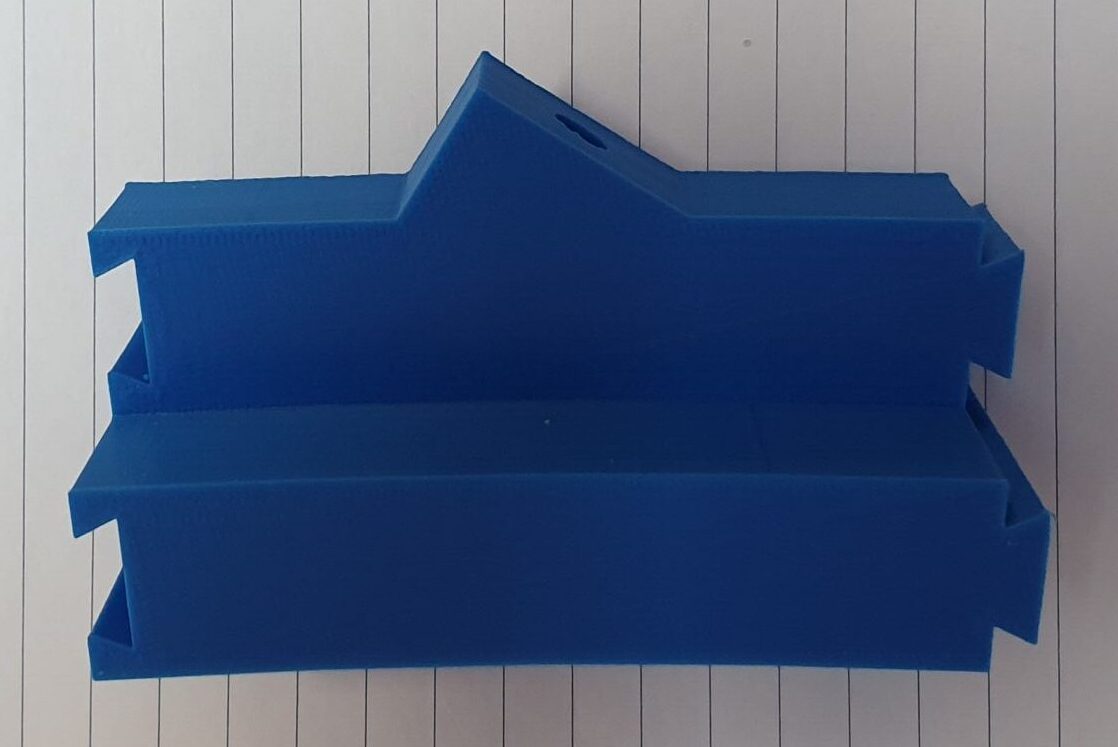

A section of a circle was 3D printed by assembling elements that divide the overall section into segments of 5 degrees each. Click on the picture to access to the 3D concept file.

The elements were printed with a fine resolution to ensure a perfect fit. The support elements (in white in the first photo) were also printed and could be easily adjusted before printing thanks to the assembly function in SolidWorks (3D view).

These segments are joined using a dovetail system, ensuring stability and precision, as shown in the associated photo.

In this photo, you can see the antennas mounted on the sliding carts on the positioning rail.